Imicu yeTungsten carbide yomatshini wokucanda

Inkcazelo emfutshane:

Imicu ye-carbide enesamente yenziwa ikakhulu ngokuxutywa kwe-WC tungsten carbide kunye neCobalt powder ngeendlela zesinyithi ezifana nokwenza umgubo, ukungqusha ibhola, ukucinezela, kunye nokuntywila. Umxholo wokubunjwa kwe-WC kunye ne-Co kwimicu ye-carbide ene-cemented ayihambelani neenjongo ezahlukeneyo, kwaye uluhlu lwabo lokusetyenziswa lubanzi kakhulu.

Iimbonakalo

Imicu ye-carbide enesamente inobulukhuni obuphezulu, ukumelana nokunxiba kakuhle, imodyuli ephezulu enwebekayo, amandla acinezelayo aphezulu, uzinzo olululo lwekhemikhali (iasidi, ialkali, ukuchasana nobushushu obuphezulu be-oxidation), ukuqina kwempembelelo ephantsi, i-coefficient yokwandiswa okuphantsi.

Inkqubo yeTekhnoloji

Ukwenza umgubo → Ifomula ngokweemfuno zokusetyenziswa → Ukusila okumanzi → Ukuxuba → Ukutyumza → Ukomisa → Ukusefa → Ukongezwa kwesixhobo sokwenza → Ukomisa kwakhona → Ukulungiswa komxube emva kokusefa → Ukuhluza → Ukucofa → Ukubumba → Ukufaka uxinzelelo oluphantsi → Ukubumba (ingenanto) → Impazamo uhlolo lokubona → Ukupakishwa → Ugcino

Iingenelo

1. AmaBanga ahlukeneyo kunye nemilinganiselo enezixhobo ezinyulu.

2. Ixesha elikhawulezayo lokuKhokela ngokuzinza kunye nomgangatho olungileyo.

3. Ubungakanani obulungiselelweyo bamkelekile

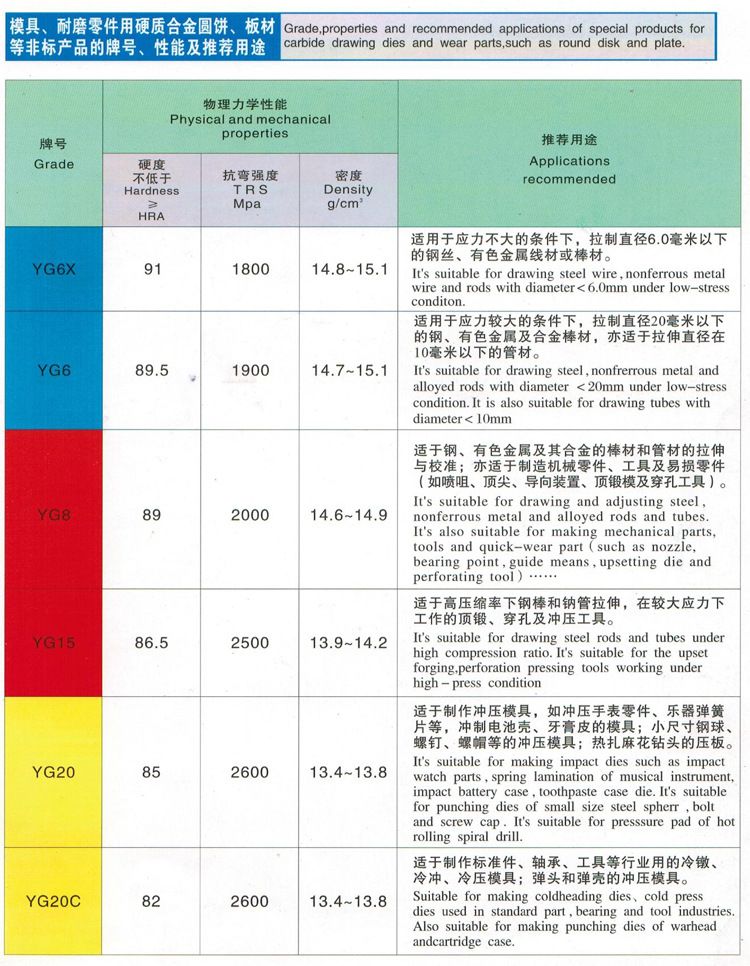

IBanga lincoma

Inkcazo

| Uhlobo(T*W*L) | Ukunyamezela kwe-T(mm) | Ukunyamezela kwe-W(mm) | Ukunyamezela kwe-L(mm) |

| 1*(2-5)*L | T≤7.0 T +0,2~+0.5

T-7.0 T +0,2~+0,6 | W≤30 W +0,2~+0.6

W>30 W +0,2~+0,8 | L<100 L 0~+1.0

L≥100 L 0~+2.0

L=330 L 0~+5.0 |

| 1.5*(2-10)*L | |||

| 2*(4-15)*L | |||

| 3*(3-20)*L | |||

| 4*(4-30)*L | |||

| 5*(4-40)*L | |||

| 6*(5-40)*L | |||

| (7-20)*(7-40)*L | |||

| Ngaphandle kwezi nkcukacha zikhankanywe ngasentla, iinkcukacha ezizodwa zinokunikezelwa ngokweemfuno zakho. | |||

FAQ

Ewe, sinokukwenza ngokweemfuno zakho.

Ngokuqhelekileyo yi-3 ~ 5 iintsuku ukuba iimpahla zikhoyo; okanye yi-10-25 iintsuku ukuba iimpahla azikho kwisitokhwe, kuxhomekeke kubungakanani bomyalelo.

Ngokubanzi asiboneleli ngeesampulu zasimahla. Kodwa sinokutsala iindleko zesampulu kwii-odolo zakho ezininzi.

Ngalo lonke ixesha isampuli yangaphambi kokuveliswa phambi kokuveliswa kobuninzi; Ngalo lonke ixesha uhlolo lokugqibela ngaphambi kokuthunyelwa.