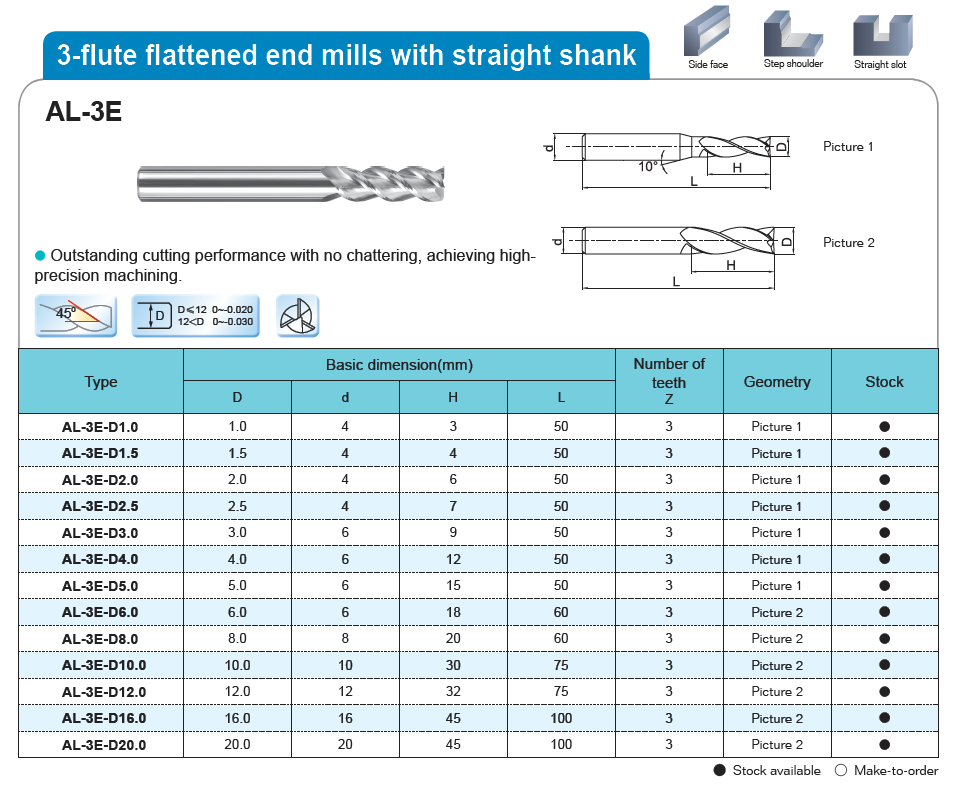

I-Cemented carbide CNC end Mill

Inkcazelo emfutshane:

AL series 3-ifleyiti ezisicaba isiphelo lokusila nge shank ngqo ekupheleni lokusila ifaneleke kakhulu AL machining.

Sinamava abanzi asebenzayo kule ntsimi kwaye sinokukunika phantse iintlobo ze-carbide end Mills.

AL series Intshayelelo

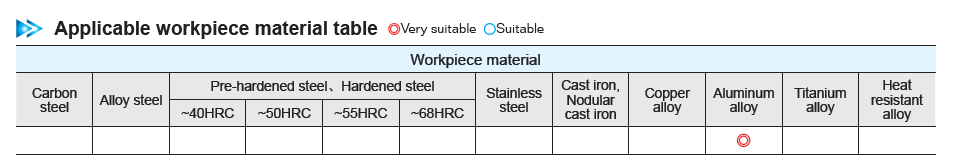

I-AL series mills isiphelo se-AL machining.AL i-series end Mills zizixhobo eziphezulu zokusika ezenzelwe izicelo zokusila. Ziyilelwe ukuba zisuse ngokufanelekileyo izinto ezivela kwizinto zokusebenza kunye nokubonelela ngokugqwesileyo komphezulu kunye nokuchaneka komda. I-AL series end Mills yakhiwe ngezinto ezikumgangatho ophezulu ezifana ne-carbide eqinileyo okanye isantya esiphezulu sentsimbi yokuqina kunye nobomi obude. Ezi zixhobo zokusila zineencam ezichanekileyo zokusika umhlaba kwaye ziza kwiintlobo ngeentlobo zejometri ezifana nesikwere, impumlo yebhola, i-radius yekona kunye neeprofayili ezirhabaxa. Uyilo lwefluti ye-AL series mill end lulungiselelwe ukunika ukukhutshwa kwetshiphu esebenzayo, ukuthintela ukwakhiwa kwetshiphu kunye nokunciphisa ukuveliswa kobushushu ngexesha lomatshini. Oku kunceda ukwandisa ubomi besixhobo kunye nokugcina ukusebenza kokusika okungaguqukiyo. Ulungelelwaniso lweFlute lunokwahluka, kuquka ezimbini, ezintathu okanye ezine uyilo lwefleyiti, ngokuxhomekeke kwiimfuno ezithile zomatshini. I-AL series mill end zifumaneka ngokobukhulu obahlukeneyo, iidiameters kunye nobude ukuze zilungele imisebenzi yomatshini eyahlukeneyo kunye nezixhobo zokusebenza. Ngokuqhelekileyo zisetyenziswa kumashishini ahlukeneyo abandakanya i-aerospace, i-automotive, ukwenza i-mold, kunye nokusetyenziswa komatshini ngokubanzi. Ngokubanzi, i-AL series end Mills zithembeke kwaye zisebenza ngeendlela ezahlukeneyo zokusika izixhobo ezibonelela ngokusebenza okuphezulu kokusika, ukuchaneka kunye nokuqina kwemisebenzi eyahlukeneyo yokugaya.

Umgangatho wesixhobo esigqwesileyo somgangatho kunye nokukhutshwa kweetshiphusi ezilungileyo ziphucula iimeko zokusika kwaye zandise kakhulu ubomi besixhobo.

Ipokotho ye-chip enemilo ekhethekileyo yenza umsebenzi oncomekayo nakwi-slot kunye ne-cavity machining.

Umphetho obukhali wokusika kunye noyilo olukhulu lwe-engile ye-helical kuthintela ngokufanelekileyo umda owakhiweyo.

Uyilo oluchasene nokungcangcazela komphetho wonke lunokucinezela ukuncokola ngexesha lomatshini kunye nokuphucula umgangatho womphezulu.

Uhlobo lwesixhobo: AL-3E-D6.0 Imilinganiselo: Ø6.0mm

Izinto eziphathekayo: LC4

Isantya esijikelezayo: 13000r/min (250m/min)

Isantya sokutya:1950mm/min (0.15mm/r)

Ubunzulu bokusika kweAxial:ap=9.0mm

Ubunzulu bokusika kweRadi: ae=1.0mm

Isimbo sokusika:Machining obunzima bomgodi

Inkqubo yokupholisa: ukuvuthela umoya

Isixhobo somatshini: MIKRON UCP 1000

Ipharamitha

Isicelo

FAQ

Ngokwemilo sineentlobo ezininzi, ezifana ne-flattened end mill, i-radius end mill, i-ball nose end mill, i-high-feed-rate end mill, i-neck end end mill, i-head end mill encinci njalo njalo.

Eyona nto ibalulekileyo yokwahluka kweemfuno zokusetyenzwa: ii-end Mills zezokugaya, ngelixa ii-drill bits zezokomba kunye nokubuyisela kwakhona. Nangona kwezinye iimeko, i-milling cutter inokwemba, kodwa ayisiyiyo eyona nto iphambili.

Ukuba uhlobo esinalo kwisitokhwe, naluphi na ubungakanani luya kulunga.

Ewe, sinokukwenza ngokweemfuno zakho.

Okokuqala, i-workpiece material.

Okwesibini, imilo kunye neenkcukacha zomlinganiso: i-shank diameter, i-flute diameter, ubude be-flute kunye nobude bebonke, inani lamazinyo.

Okwesithathu, ukuba ufuna uhlengahlengiso, sinikeze umzobo uya kuba ngcono.