#1000 ebusika ikhephu screw carbide izikhonkwane zamavili ibhayisekile

Inkcazelo emfutshane:

Izikrufu, ezaziwa ngokuba zizikrufu ezingatyibilikiyo. zizikrufu eziyilwe ngokukodwa ezenzelwe ukubonelela ngokusebenza okunamandla okuchasa ukutyibilika. Ngokuqhelekileyo inezi mpawu zilandelayo: ukusebenzisa iingcebiso ze-tungsten carbide pin, ibe nokumelana okugqwesileyo kunye nokusebenza kokuqina.

Ukuqulunqwa kwemveliso

| Igama | Izikhonkwane zamatayara eCarbide | Iintlobo | 1000 | |

| Isicelo | Iibhayisekile, Izihlangu | Iphakheji | Ingxowa yeplastiki/ibhokisi yephepha | |

| Izinto eziphathekayo | Carbide pin okanye cermet pin + carbon steel umzimba | |||

| Umzimba we-studs | Izinto eziphathekayo: Intsimbi yekhabhoni Unyango olungaphezulu : Ukufakwa kwegalvanization | |||

Ingcebiso

Xa ibhayisekile ikhwele kwindlela emtyibilizi okanye enomkhenkce, izikhonkwane zamatayara ebhayisikile zinokungena kumkhenkce okanye kwikhephu, zandise ukukhuhlana phakathi kokunyathela kunye nomhlaba, zinike ukubamba ngcono nokuzinza, kwaye zithintele ukutyibilika nokuntlitheka.

Xa usebenzisa izikhonkwane zamatayara ebhayisekile, kufuneka ubeke ingqalelo kula manqaku alandelayo:

1.Qinisekisa ukuba ukhetha ubude obufanelekileyo kunye nenani lee-studs ezihambelana neemeko zendlela ezahlukeneyo kunye neemfuno zokukhwela.

2.Xa ufaka, qiniseka ukuba izikhonkwane zifakwe kwisinyathelo ukuya kubunzulu obufanelekileyo kwaye ungonakalisi ityhubhu yangaphakathi.

3.Qaphela ukuba uhlole kwaye ugcine iinzipho zakho rhoqo ukuze uqinisekise ukuvakala kwazo kunye nokuqina kwazo

Iimbonakalo

①100% imathiriyeli ekrwada enepini ye-tungsten carbide enganxibiyo

②98% iphucula ukuchasana kwe-slip

③ uhambo olukhuselekileyo noluthembekileyo

④ kulula ukuyifaka kunye nokususwa

⑤ Uyilo lwemisonto ye-auger ebanzi yenza ukukhwela kuzinze ngakumbi

⑥intengiso eshushu eYurophu naseMelika

Iiparamitha

98% UKUPHUCULA OKUCHASELEKILEYO

I-Wide auger Screw-In Tire Stud 1000# ilungele amatayara ebhayisekile

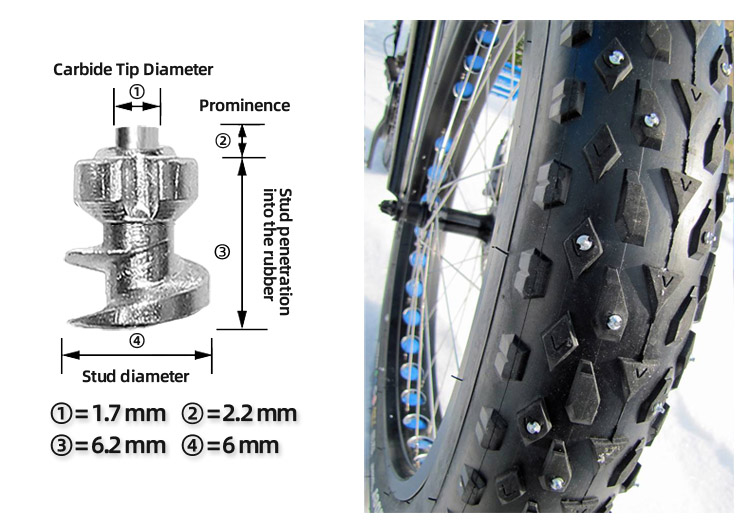

IiParameters zeMveliso (UNIT:mm)

| Uhlobo lweMveliso | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | 1600 | 1700 | 1740 | 1750 |

| Umfanekiso weMveliso |  |  |  |  |  |  |  |  |  |  |

| Imilinganiselo ye-Dimensions X yoBubude buBonke | 6X8.4 | 7.9X9.8 | 9x12.6 | 9x15.2 | 9x16.3 | 9x17.5 | 7.7x16.6 | 9x20.8 | 7.7x17.4 | 7.7x20.9 |

| Ukubalasela | 2.2 | 1.9 | 1.9 | 3.2 | 2.8 | 4 | 3.6 | 7.3 | 5.4 | 6.9 |

| Ukungena kwe-Stud kwiRubber | 6.2 | 7.9 | 10.7 | 12 | 13.5 | 13.5 | 13 | 13.5 | 12 | 14 |

| Ubuncinane boNyathelo lweMilinganiselo ngokubanzi | 5 | 5.9 | 8.5 | 9.5 | 11 | 11 | 10.5 | 11 | 9.5 | 11.5 |

| Carbide Tip Diameter | 1.7 | 2.2 | 2.6 | 2.6 | 2.6 | 2.6 | 2.2 | 2.2 | 2.2 | 2.2 |

| Uhlobo lweMveliso | 1800 | 1800R | 1900 | 1910 | 1910T | 1911 | 1912 | 3000A | 3000B |

| Umfanekiso weMveliso |  |  |  |  |  |  |  |  |  |

| Imilinganiselo ye-Dimensions X yoBubude buBonke | 9x23.3 | 9x24.5 | 9x20.5 | 10x19 | 10x23.8 | 11x22.8 | 12x24.5 | 7.9x15.1 | 7.9x11.4 |

| Ukubalasela | 6.8 | 8 | 4 | 4.5 | 5.3 | 5.3 | 6 | 4.4 | 3 |

| Ukungena kwe-Stud kwiRubber | 16.5 | 16.5 | 16.5 | 14.5 | 18.5 | 17.5 | 18.5 | 10.7 | 8.4 |

| Ubuncinane boNyathelo lweMilinganiselo ngokubanzi | 14 | 14 | 14 | 11.5 | 16 | 14.5 | 15.5 | 7.5 | 5.8 |

| Carbide Tip Diameter | 2.6 | 2.6 | 2.6 | 3 | 3 | 3.5 | 3.5 | 2.2 | 2.2 |

Ukuhlohla

FAQ

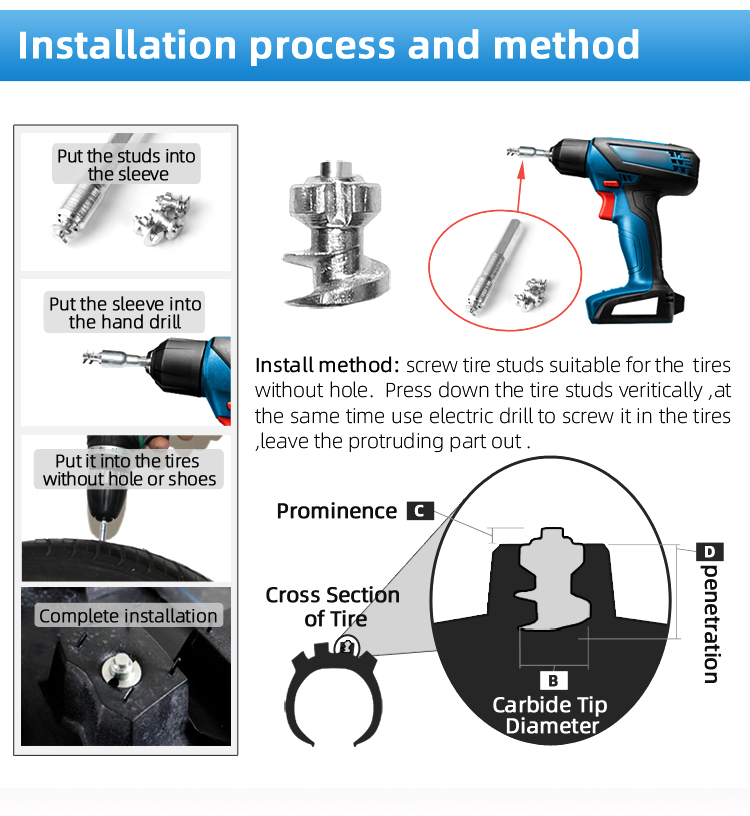

Khetha ubungakanani obufanelekileyo kwaye uyifake ngendlela eyiyo, ayizukugqobhoza amatayara. Ngenxa yokuba ubunzulu bofakelo buhlala bufana nobude bepateni yerabha yokunyathela .Unako kwakhona ukuqhawula kwitayara xa ungayisebenzisi.

Izikhonkwane zamaTire sele ziluhlobo lweemveliso ezivuthiweyo. Isetyenziswa kwihlabathi liphela eYurophu naseMelika. Ukuyifaka kunye nokuyisebenzisa ngokuchanekileyo akuyi kubachaphazela ubomi bamathaya. Kungenjalo, amatayara ngokwawo ayinto enokutyiwa, kukho iimfuno ezithile malunga nemida yobudala kunye neekhilomitha ezihanjiweyo. Kufuneka siyijonge kwaye siyitshintshe rhoqo.

Xa uqhuba kwindlela enomkhenkce, kulula ukutyibilika . amatayara angakugcina ukhuselekile. Ifakwe kumphezulu werabha yesondo ngokuthe ngqo, yenza uzinzile. Phucula ukuncamathelisa, ukwenza ukuba ukuqhuba kuzinzile, kungabikho ukutyibilika.

Iingcebiso: izikhonkwane zamatayara azinamandla onke. Kukhuseleko lwakho lokuhamba, Ukuqhuba ngononophelo yeyona nto ibalulekileyo.

1). Amatayara anomngxunya, sinokukhetha izikhonkwane zamatayara emilo yerivet okanye imilo yekomityi yamavili. Amatayara ngaphandle komngxuma, sinokukhetha izikhonkwane zamatayara.

2). Kufuneka silinganise i-diameter yomngxuma kunye nobunzulu bamatayara (amatayara anomngxuma); Ifuna ukulinganisa ubunzulu bepateni yerabha yokunyathela kwitayara lakho (amatayara angenamngxuma), emva koko ukhethe ezona zitya zifanelekileyo zifanelekileyo kwitayara lakho.

3). ngokweedatha zokulinganisa, sinokukhetha ubungakanani be-studs ngokusekwe kumatayara akho kunye neendlela ezahlukeneyo zokuqhuba. Ukuba uqhuba kwindlela yedolophu, sinokukhetha ubungakanani obuncinci bokuvelela. Xa uqhuba kwindlela enodaka, kumhlaba onesanti kunye nendawo eshinyeneyo yekhephu yomkhenkce, sinokukhetha ubungakanani obukhulu bokuduma, ukwenza ukuqhuba kuzinze ngakumbi.

Akukho ngxaki ukufaka izigxobo zamatayara wedwa. Kulula noko. Ungayifaka ngesandla okanye usebenzise izixhobo zombane ukuphucula ukusebenza kakuhle. Siza kukubonelela ngevidiyo yokufakela.

Inokususwa ngokwexesha lonyaka, kwaye inokuqhathwa xa ungasetyenziswanga kwakhona kwixesha lonyaka elilandelayo.

Ewe, singakunika iisampulu, unoxanduva lweendleko zokuthumela ngenqanawa.